SUMMARY

YANMAR Multipurpose Vegetable Transplanter PH1-KWA is 2 rows by going and returning transplanters on high ridge with wide tread for cabbage, Chinese cabbage, cauliflower, spinach, broccoli and many leaf vegetables.

The YANMAR Multipurpose Vegetable Transplanter PH1 reduces labor during vegetable transplanting.

The YANMAR Multipurpose Vegetable Transplanter PH1 series are light-weight and compact transplanters.

The YANMAR Multipurpose Vegetable Transplanter PH1 can transplants seedlings on cell trays and general plastic pots.

OPERABILITY

The YANMAR Multipurpose Vegetable Transplanter PH1 adjusts the height of handle with 4 steps according to the height of ridge or operator. By adjusting the handle height, it reduces the labor on long planting work.

By lifting the handle to upper positions, the YANMAR Multipurpose Vegetable Transplanter PH1 lifts the front wheels and turns around easily.

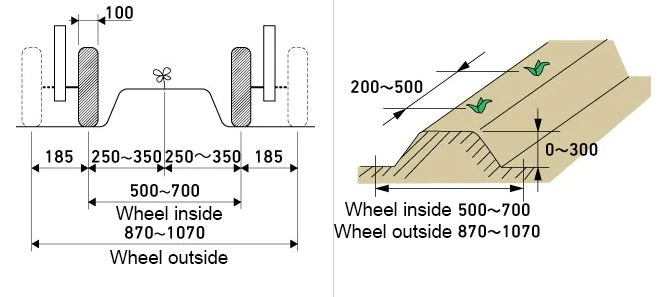

The YANMAR Multipurpose Vegetable Transplanter PH1 is designed to locate control levers around the handle that allows efficient operations.

The control levers are universal design and they are easily recognized.

The YANMAR Multipurpose Vegetable Transplanter PH1 has a planting distance gauge that is useful during adjusting the planting distance.

The YANMAR Multipurpose Vegetable Transplanter PH1 stops operation after moving the supplying holes to top when the planting clutch is turned off.

This feature prevents the planting device from touching the ridges and mulch.

WORKABILITY

The YANMAR Multipurpose Vegetable Transplanter PH1 has an engine that meets the emissions regulations in Japan.

The YANMAR Multipurpose Vegetable Transplanter PH1 has an automatic oil pressuring up/down function and parallel link structure. It keeps the planting depth and position stably.

It has a roller type sensor that detects the surface of ridge smoothly. The YANMAR Multipurpose Vegetable Transplanter PH1 keeps the planting depth even on the uneven ridges or wet ridges.

The oil pressuring horizontal control keeps the frame horizontal even in the sloping and soft ground.

The YANMAR Multipurpose Vegetable Transplanter PH1 is designed to open and close the seedling holding part after planting as to avoid taking off seedlings or plastic mulch.

The tread of the YANMAR Multipurpose Vegetable Transplanter PH1 is adjustable without a tool by holding the frame on the attached stand.

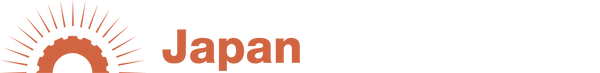

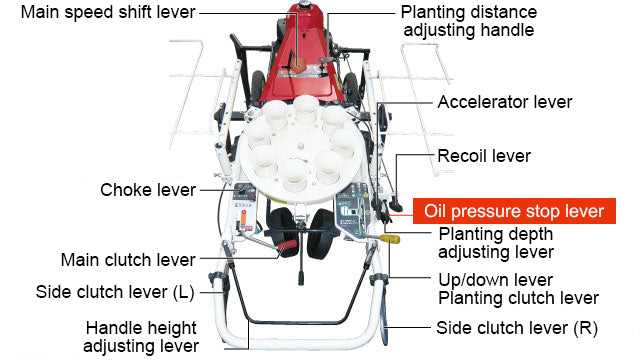

RIDGE SHAPES

The YANMAR Multipurpose Vegetable Transplanter PH1-A applies many types of ridge shapes.

OPTIONS

We have a variety of option devices designed for PH1 Transplanter series. Please ask us for more information.

PH1,A SERIES

We have 6 models of PH1,A series.

| Series | Model | Vegetable | Remarks |

|---|---|---|---|

| PH1 | A | Cabbage Chinese cabbage Broccoli etc |

1 row/1 ridge |

| WA | 2 rows by going and returning | ||

| KWA | 2 rows by going and returning (high ridge) | ||

| JA | Potato | 1 row/1 ridge | |

| SA | Taro | 1 row/1 ridge | |

| BWA | Edamame | 2 rows by going and returning |

SPECIFICATIONS

| Model name | Multipurpose Vegetable Transplanter | ||||

|---|---|---|---|---|---|

| Model number | PH1 | ||||

| Type | A (standard, 1 row/1 ridge) |

WA (wide, 2 rows by going and returning) |

KWA (wide, high ridge, 2 rows by going and returning) |

||

| Dimension | Length (mm) | 1900 | 1900 | 1900 | |

| Width (mm) | 1340 | 1440 | 1440 | ||

| Height (mm) | 960 | 960 | 1010 | ||

| Weight (kg) | 155 | 165 | 170 | ||

| Engine | Engine model | GB101LN | |||

| Type | Air-cooling 4 cycle engine | ||||

| Total engine displacement (L (cc) ) | 0.098 (98) | ||||

| Output / Rotational speed (kW (PS) /rpm) |

1.6 (2.2) /1800 | ||||

| Maximum output (kW (PS) ) |

2.2 (3.0) | ||||

| Fuel type | Automobile lead-free gasoline | ||||

| Fuel tank capacity (L) | 2.0 | ||||

| Starting method | Recoil starter | ||||

| Driving | Wheel | Front | Rubber wheel ρE370 (3.00-8) |

Rubber wheel ρE370 (3.00-8) |

Rubber wheel ρE425 (3.00-10) |

| Back | Rubber wheel ρE445 (4.00-8) |

Rubber wheel ρE445 (4.00-8) |

Rubber wheel ρE545 (5.00-12) |

||

| Tread adjustment | Hexagonal pipe sliding method | ||||

| Tread (mm) | 500 - 700 (Wheel inside) 870 - 1070 (Wheel outside) |

1000 - 1525 (Wheel inside) |

1000 - 1525 (Wheel inside) |

||

| The number of shift steps | Forward 2, backward 1 | ||||

| Speed | Planting (m/s) |

0.32 | 0.32 | 0.39 | |

| Driving on the road (m/s) |

0.83 | 0.83 | 1.02 | ||

| Body up/down control | Oil pressuring automatic following | ||||

| Body up/down method | Front and back up/down, parallel link | ||||

| Body horizontal control | Oil pressuring automatic method | ||||

| Inclined angle value (degree) | Left and right 8 to 10 | Left and right 4 to 5 | Left and right 4 to 5 | ||

| Planting | The number of planting rows | 1 | 1 (2 rows by going and returning) | 1 (2 rows by going and returning) | |

| Row distance (mm) | - | 250 - 600 | 250 - 600 | ||

| Ridge height (mm) | 0 - 300 | 0 - 300 | 100 - 350 | ||

| Planting distance adjustment method | Gear 3 shifts + non-step pulley | ||||

| Planting distance (mm) | 200 - 500 | 200 - 500 | 240 - 550 | ||

| Planting depth adjustment (step) | 15 steps | ||||

| Planting method | Opening hole device | ||||

| Seedlings supplying method | Rotary pot supplying method | ||||

| Operating efficiency (hour/10a) | 2.5 - 3.5 | ||||

| The number of cell trays | 2 | 2 | 2 | ||

| Seedling type |

Cell trays |

Cell trays Plastic pots |

Cell trays Plastic pots |

||

| Safety inspection number | 27127 | 27127 | 27127 | ||