VIDEO

SUMMARY

Carrot harvesting work is greatly lightened!

The fastest digging speed in its class significantly reduces labor time!

The carrot harvester, which can perform 6 processes in a single machine, further reduces the amount of labor required for harvesting carrots.

Two storage systems available

1. Mini container type (HN114-CU)

Up to 11 mini-containers can be loaded.

Equipped with rollers

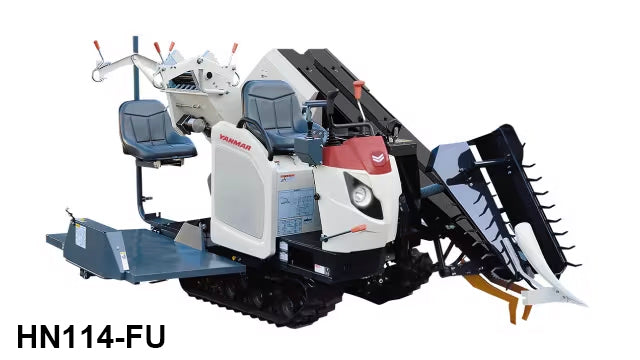

2. Flexible container bag type (HN114-FU)

Spare flexible containers can be hung on hooks behind the assistant's seat (max. 4 bags).

Flexible container unloading method

Quick hanger

Stop Switch

FEATURES

Vibratory Soilers

Vibratory soiler floats carrots out of the soil and pulls them out without difficulty even in hard ground. The special steel specifications provide high abrasion resistance.

Root cutter

A three-blade root cutter cuts the root tips. Roots are cut with high precision even at high conveyor speeds to achieve a clean finish.

Tapping Chain + Cutting Blade

A unique chain is used for cutting stems and leaves and aligning shoulders. The transport posture to the cutting section is maintained at a constant level, enabling cutting with aligned shoulders even at high speeds. The cutting height can be adjusted to accommodate carrots for processing.

Remaining leaf treatment roller

Leaves left over at the cutting section are removed cleanly by the leaf treatment roller. The inverted root discs under the cutting blades turn the carrots in the right direction for highly accurate remaining leaf treatment, saving the labor of assistants and allowing for more time for sorting.

Concentrated placement on the work seat side

Allows simultaneous operation of left/right turning and digging section up/down.

Equipped with a pad for convenient wrist fixation. This reduces fatigue even during long hours of work.

Allows operation of the puller, root cutter, and each conveyor.

Automatic and manual vehicle leveling control function

SPECIFICATIONS

| Model name | HN114 | ||||

| Classification | CU | FU | |||

| Dimensions | Length (when working) (mm) | 3220 (3360) | 3230 (3270) | ||

| Width (when working) (mm) | 1680 (2260) | 1820 (2350) | |||

| Height (when working) (mm) | 1585 (1585) | 1620 (2065) | |||

| Weight (kg) | 1000 | 1050 | |||

| Engine | Model name | Water-cooled 4-stroke, 2-cylinder diesel engine |

|||

| Total Displacement (L) | 0.688 | ||||

| Output/Rpm (kW/rpm) | 10.7 / 2600 | ||||

| Fuel Tank Capacity (L) | 14 | ||||

| Traveling section | Crawler | Center distance (mm) | 750 | ||

| Width x Ground length (mm) | 280 x 933 | ||||

| Variable system | HST, 3-step sub-shift | ||||

| Speed | Forward | Work speed (m/s) | 0 - 0.94 | ||

| Drive speed (m/s) | Low speed: 0 - 0.62 Travel: 0 - 1.7 |

||||

| Backward (m/s) | 0 - 1.4 | ||||

| Steering direction | Multi-power steering lever (1 lever) | ||||

| Digging section position | Offset 40mm from left end of crawler | ||||

| Pulling method | Vertical: 1 Horizontal:1 (rubber lug belt system) |

||||

| Digging section | Digging method | Narrow hold and pull system | |||

| Soiler | Vibration type 2 lever | ||||

| Gauge wheel | DOP (interlocking type) | ||||

| Applicable stem root length (mm) | 250 - 700 | ||||

| Shoulder alignment section | Shoulder alignment | Special chain system | |||

| Cutting method | Scraping disk cutter (with inverted root disk) |

||||

| Cutter height adjustment | Stepless (tool-less) | ||||

| Cutting height adjustment range (mm) | -17~+9 (For processing business use) | ||||

| Applicable carrot | Length (mm) | Less than 300 | |||

| Thickness (mm) | 25 - 75 | ||||

| Storage section | Storage system | Mini container (11 pcs) |

Flexible container (200 kg) |

||

| Flexible conveyor height adjustment | Electric cylinder | ||||

| Flexible conveyor lowering system | Electric dumping system (front and rear) |

||||

| Applicable swell height (mm) | Less than 150 | ||||

| Applicable row spacing (mm) | 150 or more | ||||

| Work efficiency (pcs/hr) | 12100 - 24200 | ||||