Brown rice is covered with a layer of bran. The process of removing the bran and hulls from the brown rice is called milling. Polishing is done to improve digestion, absorption, and taste, and the rice we usually eat is the rice after polishing.

In this article, we will introduce the rice milling process used by Japanese farmers.

1. Japanese Rice-polishing System

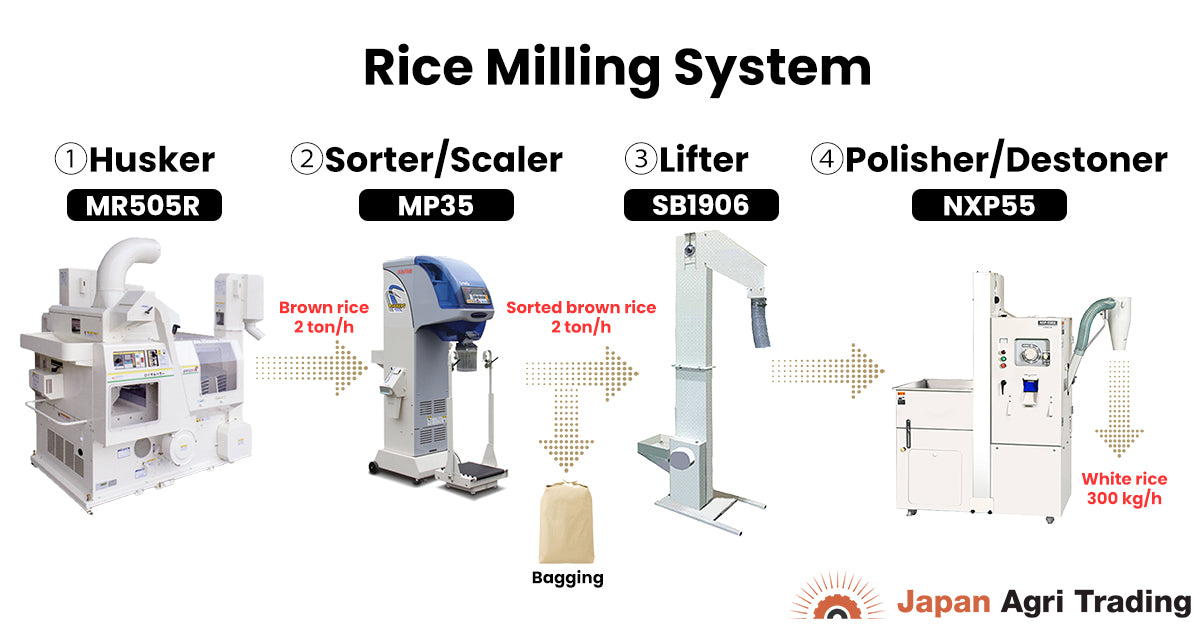

The rice milling process used by Japanese farmers is a seamless system that combines husker, bagging sorter, lifter, and polisher. Japanese rice farmers prefer this style of milling because brown rice is stored in paper bags and can be milled at any time.

The following is a step-by-step explanation of the rice milling process.

2. Process of rice milling system

1) Husker

First, huskers are used to remove the hulls from the unhulled rice to make brown rice.

2) Bagging sorter

This machine is used to pack the brown rice finished by the husker into bags. The bagging sorter allows the rice bags to be easily attached to and detached from the bag holder. The bagged brown rice is stored in the bag until it is time for milling.

3) Lifter

The lifter is used to adjust the height of the bagged brown rice to the appropriate level so that the rice is poured into the polisher's sink, which is used in the next process.

4) Polisher

The brown rice poured through the lifter is polished by removing bran through the polisher.

This is Japanese rice milling system. We also sell products for all four parts of the system, so please check out our website for more information.

Check our Rice category.