SUMMARY

YANMAR Onion Transplanter PH2 transplants onion seedlings and reduces a lot of labor.

The YANMAR Onion Transplanter PH2 plants 4 rows by going and returning at 24cm row distance.

This YANMAR Onion Transplanter PH2-TW24A has guide roller and watering device.

OPERABILITY

The YANMAR Onion Transplanter PH2 has control levers around the handle. It helps to control transplanting efficiently.

The planting distance gauge indicates the planting distance clearly.

The YANMAR Onion Transplanter PH2 is designed to open and close the seedling holding part after planting in order to avoid taking off seedlings or plastic mulch.

WORKABILITY

The YANMAR Onion Transplanter PH2 has an engine that meets the emissions regulations in Japan.

The YANMAR Onion Transplanter PH2 can be operated by one person for two rows transplanting by supplying seedlings to rotary pots. The YANMAR Onion Transplanter PH2 has 32 rotary pots that slowly turns around that is convenient for one-person or two-person operations.

The YANMAR Onion Transplanter PH2 has the parallel link structure. The sensor also detects the surface of the ground and move up/down by oil pressuring. The YANMAR Onion Transplanter PH2 keeps the planting depth and position stably.

The YANMAR Onion Transplanter PH2 covers ground just after transplanting seedlings. The YANMAR Onion Transplanter PH2 presses ground firmly and it helps the seedlings to extend roots well.

The tread of front and rear wheels can be adjusted from 100 to 135cm.

The YANMAR Onion Transplanter PH2 has a mulch cutting device that opens holes on plastic mulch along with transplanting.

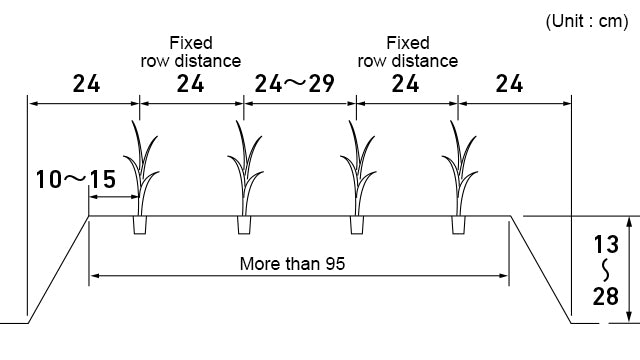

The YANMAR Onion Transplanter PH2 transplants onion seedlings with fixed row distance. At the harvest time, it helps to harvest onions by harvester.

The YANMAR Onion Transplanter PH2 removes the soil every time after transplanting and it helps to stabilize transplanting accuracy.

RIDGE SHAPES

Row distance: 20cm

Row distance: 24cm

OPTIONS

We have a variety of option devices designed for PH2 Onion Transplanter series. Please ask us for more information.

PH2 SERIES

We have 3 models of PH2 Onion Transplanter series.

| Model | Type | Vegetable | Remarks |

|---|---|---|---|

| PH2 | TWA | Onion (onion leaf) | 4 rows by going and returning Row distance 20cm (24cm) |

| TW24A | 4 rows by going and returning Row distance 24cm (20cm) (including guide roller and watering device) |

||

| VWA | Onion (onion leaf) Lettuce and other vegetables |

4 rows by going and returning Row distance 20cm (24cm) (including planting distance change lever) |

SPECIFICATIONS

| Model name | Onion Transplanter | ||||

|---|---|---|---|---|---|

| Model number | PH2 | ||||

| Type | TWA Standard (4 rows by going and returning: row distance 20cm) |

TW24A Guide roller and watering device included (4 rows by going and returning: row distance 24cm) |

VWA Planting distance change lever included (4 rows by going and returning: row distance 20cm) |

||

| Dimension | Length (mm) | 1935 | 2315 | 1935 | |

| Width (mm) | 1250 | ||||

| Height (mm) | 1260 | ||||

| Weight (kg) | 215 | 235 | 215 | ||

| Engine | Engine model | GB101LN | |||

| Type | Air-cooling 4 cycle gasoline engine | ||||

| Total engine displacement (L (cc) ) | 0.098 (98) | ||||

| Output / Rotational speed (kW (PS) /rpm) |

1.6 (2.2) /1800 | ||||

| Maximum output (kW (PS) ) |

2.2 (3.0) | ||||

| Fuel | Automobile lead-free gasoline | ||||

| Fuel tank capacity (L) | 2.0 | ||||

| Starting method | Recoil starter | ||||

| Driving | Wheel | Front | Rubber wheel ρE425 |

Rubber lug wheel ρE460 |

Rubber wheel ρE425 |

| Back | Rubber lug wheel ρE600 | ||||

| Tread adjustment | Hexagonal pipe sliding method | ||||

| Tread (mm) | 1000 - 1350 | ||||

| The number of shift steps | Forward 2, backward 1 x 2 (sub shift) | ||||

| Speed | Planting (m/s) |

0.085 - 0.167 | |||

| Driving on the road (m/s) |

1.0 | ||||

| Body up/down control | Oil pressuring automatic following | ||||

| Body up/down method | Front and back up/down, parallel link | ||||

| Planting | The number of planting rows | 2 | |||

| Row distance (mm) (*1) | 200 <240> | 240 <200> | 200 <240> | ||

| Ridge height (mm) | 125 - 275 | ||||

| Planting distance adjustment method | Non-step pulley handle adjustment | Gear 3 shifts + non-step pulley | |||

| Planting distance (mm) | 100 - 130 | 100 - 270 | |||

| Planting depth adjustment | 15 steps | ||||

| Planting method | Opening hole device | ||||

| Seedlings supplying method | Rotary pot supplying method | ||||

| Operating efficiency (hour/10a) | 5 - 6 (by 2 persons) | ||||

| The number of cell trays | 4000 pieces of seedlings | ||||

| Seedling type (*2) | Onion seedlings YANMAR vegetable tray 20 |

Onion seedlings YANMAR vegetable tray 20 , 25 corner |

|||

| Safety inspection number | 27128 | ||||

*1:The row distance can be adjusted by changing the left and right side of seedling put devices.

*2: Seedlings height is about 15cm.