VIDEO

SUMMARY

Significantly Shorten Harvesting Work Hours to Expand Long Onion Cultivation

Harvesting long onions is hard work that involves breaking the ridges while digging and removing soil from the roots.

HL10 is a labor-saving solution. The amount of time is greatly reduced by making ridge breaking, digging, dirt removal, and bundling into one process. Adjacent digging is made possible, and this contributes to cultivation on a greater scale.

Received the Development Award from the Japanese Society of Agricultural Machinery Engineers.

The long onion harvester’s improved features were highly praised for their increased efficiency and workability as well as their ability to reduce labor.

*The details of the image model may differ from the current product due to improvements, etc.

WORKABILITY

Long Onion Harvesting Simplified to Reduce Labor!

Ridge breaking, digging, dirt removal, are bundling are combined into a single process, and long onions are transported gently and carefully on a conveyor belt. Labor is greatly reduced.

![]()

Comparison of Time Spent from Digging to Bundling/Binding

| Product | Warking timeE½i100mE½j |

|---|---|

| HL10 | 60E½`90min |

| Tiller | 230min |

| Tractor | 200min |

*Based on in-house test

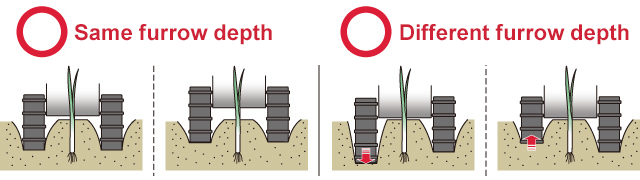

Adjacent Digging Made Possible

Body Level Adjustment (Manual UFO)

On conventional machines HL1, adjacent digging needed [optional item] for the digging blade.

The HL10’s left crawler can be adjusted 80mm higher or lower. This makes it possible to harvest in varying groove depths, and optional item is not needed for adjacent digging.

Gently Harvest and Transport

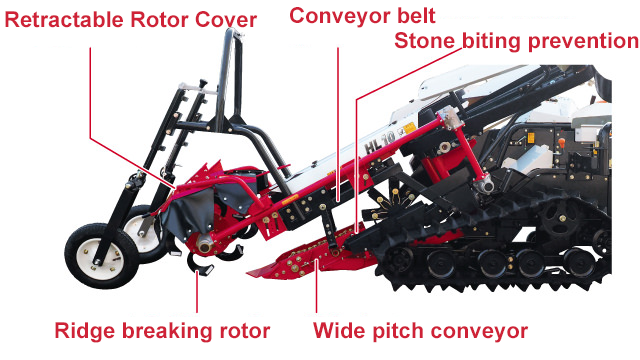

Ridge-breaking rotor + Digging conveyor + Conveyor belt

The ridge-breaking rotor breaks up the dirt on the sides, and the digging conveyor and conveyor belt gently hold the long onions while transporting them. Transportation space is increased, which helps improve soil drainage and increases stability in transportation.

Retractable Rotor Cover

The rotor cover can be opened or closed depending on the situation, such as closing it to prevent dirt from getting on the long onions, or opening it to remove dirt from the machine.

Stone Damage Prevention Structure

The digging conveyor’s idler roller has a structure that prevents stones from getting in the machine.

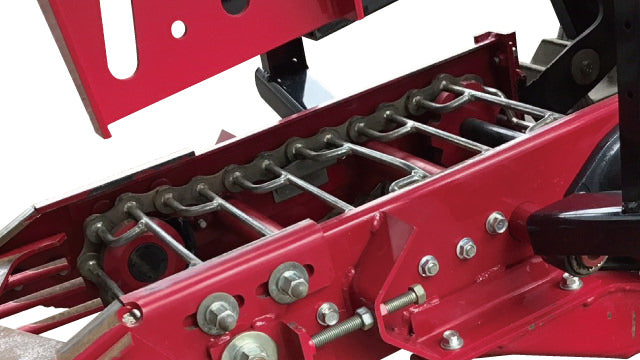

Wide Pitch Conveyor

Equipped with a standard 66mm pitch conveyor. Soil drainage performance is further improved.

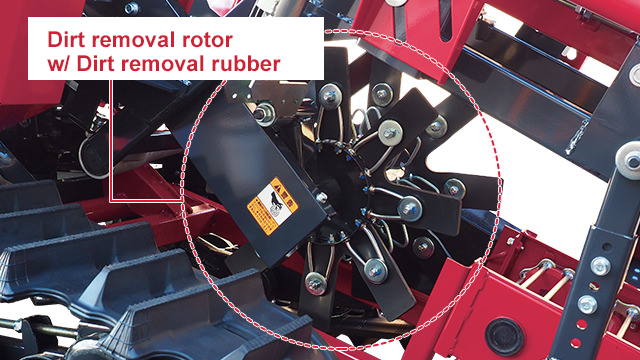

Improved Dirt Removal Performance

Rubber Dirt Removal Rotor

Dirt removal performance has been improved through the addition of dirt-removing rubber and a heightened rotation speed of 1.6 times that of conventional machines. Dirt on the roots is removed during transportation, eliminating the extra step of doing it later. Even if the rotor wears out, it can easily be replaced.

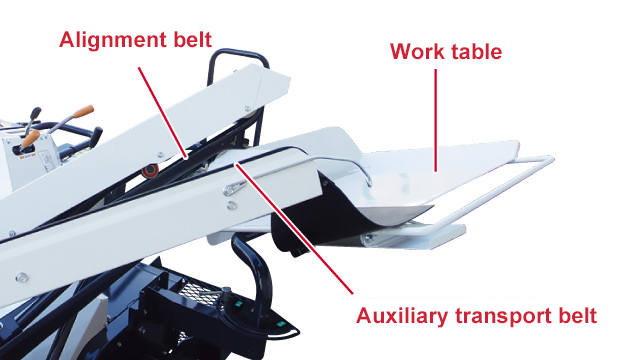

Bundling/Binding While Harvesting

Auxiliary Transport Device + Work Table

•✁E/span>Work table can hold net for harvesting long onions. Binding can be done with either net or string.

•✁E/span>Align the roots using the work table’s side plate.

•✁E/span>New auxiliary transport device that transports long onions without damage. Work can be done smoothly at the work table.

Reduced Labor

Step Stool

You can stand on the step stool while they work, making bundling/binding easy.

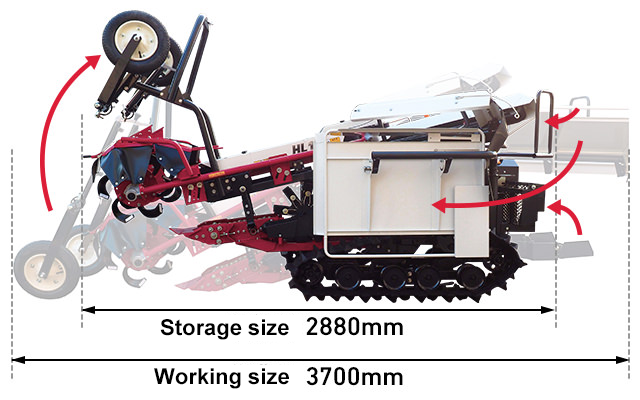

Compact Storage

No Tools Necessary for Storage

No tools are necessary, and gauge wheel can be flipped up and work table left on its side. While being stored, it can be shorted by 820mm of its working size.

OPERABILITY

Stable Running along the Ridges

Gauge Wheel with Adjusting Handle and UFO Lever

Digging depth is kept stable and damage to the long onions is prevented. The gauge wheel has lines which make it easy to align the height on the left and right sides. The gauge wheel has a greater range for up-down adjustment than conventional machines, and the adjusting handle is easier to operate. Left-right adjustment is also possible and no tools are necessary. The gauge wheel runs following the ridges, so while it runs you can focus on bundling and binding.

The machine body can be moved to the left or right using the UFO lever.

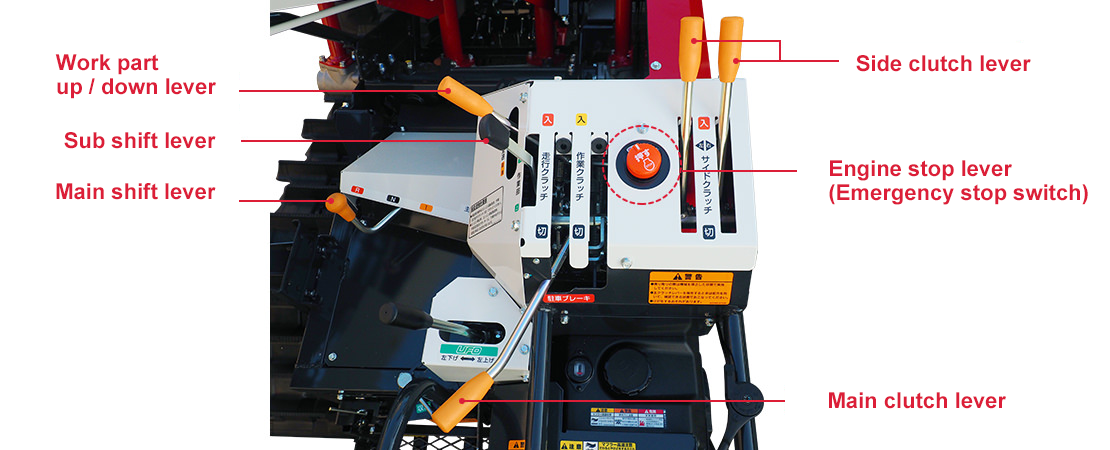

Easy to Operate

Operating Levers All Within Reach

All the levers used frequently while working are in one place and easy to reach.

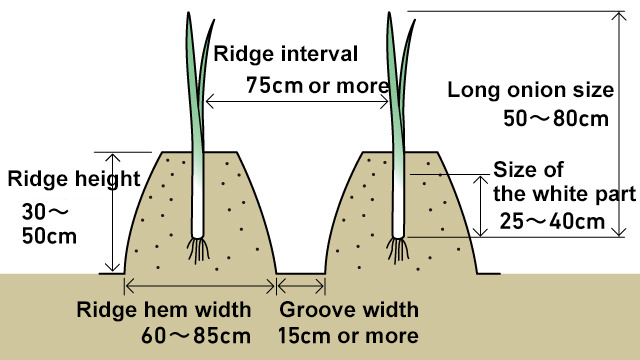

ADAPTABLE CONDITION

Ridge Shape

*Does not apply to specialized crops such as bent onions

Crop

Long onion (also called as green onion or leek)

SPECIFICATIONS

| Model | YANMAR Long onion Harvester | ||

|---|---|---|---|

| Model Number | HL10 | ||

| Type | U | ||

| Dimension | LengthE½immE½j | 2880E½i3700 when workingE½j | |

| WidthE½immE½j | 1325E½i1705 when workingE½j | ||

| HightE½immE½j | 1430E½i1485 when workingE½j | ||

| WeightE½ikgE½j | 624 | ||

| Engine | Model | GB181LN | |

| Type | Air-cooling 4 cycle OHV gasoline engine | ||

| Total displacementE½iLE½occE½pE½j | 0.181E½o181E½p | ||

| Rated output/rotation speedE½ikWE½oPSE½p/rpmE½j | 3.4E½o4.7E½p/1800 | ||

| Maximum outputE½ikWE½oPSE½pE½j | 4.6E½o6.3E½p | ||

| Fuel tank capacityE½iLE½j | 3.6 | ||

| Starting method | Recoil starter | ||

| Driving | Crawler | Width x Grounding lengthE½immE½j | 250ÁE91 |

| Center distanceE½immE½j | 720 | ||

| Average ground pressureE½ikPaE½okgf/cm2E½pE½j | 15.4E½o0.157E½p | ||

| Shift method | Mechanical type | ||

| Running speed | ForwardE½im/sE½j | Min. speed: 0.05 in 1st gear (working gear), 0.18 in 2nd gear | |

| backwardE½im/sE½j | Max. speed: 0.25 in 1st gear, 0.89 in 2nd gear | ||

| Steering clutch type | Claw | ||

| Body level adjustment | Manual (hydraulic one side vehicle height adjustment mechanism) | ||

| Operation | Digging | Number of rows dugE½irowE½j | 1 |

| Digging widthE½immE½j | 200E½iBar conveyor widthE½j | ||

| Digging method | Bar conveyor | ||

| Lifting method of harvester part | Linked to hydraulic (double-action cylinder) digging up section | ||

| Method of dirt removal | Sides: Rubber sheets; Underneath: Drum with raised protrusions | ||

| EfficiencyE½iRidge interval 1mE½ERidge length 50mE½jE½imin/10aE½j | 900 | ||

| Safty number | 40105 | ||