SUMMARY

The YANMAR Full Automatic Vegetable Transplanter is a high-speed model for transplanting cabbage, Chinese cabbage, broccoli and lettuce. It is designed to reduce labor and manpower during transplanting process.

The YANMAR Full Automatic Vegetable Transplanter PW10-M transplants 1 row on 1 ridge covered with plastic mulch by cutting mulch.

We have 7 models of PW10 series with different features and options.

WORKABILITY

The YANMAR Full Automatic Vegetable Transplanter PW10-M cuts plastic mulch by a electric heater that is not affected by rain or wind.

The YANMAR Full Automatic Vegetable Transplanter PW10-M transplants seedlings at the center of the hole cut on plastic mulch.

Needle claw takes out seedlings carefully. Claw cover protects seedlings.

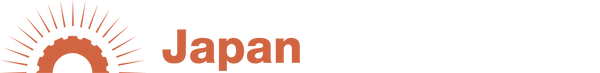

Soil covering rollers cover soil over the seedlings and avoid the soil entering to the shaft.

Soil covering adjustment lever changes the weighing of covering soil and covers the seedlings stably.

The YANMAR Full Automatic Vegetable Transplanter is designed to transplant seedlings with optimum movements that avoid damaging to seedlings.

The YANMAR Full Automatic Vegetable Transplanter is increased the hardness of the frame that enables to transplant seedlings on a straight line.

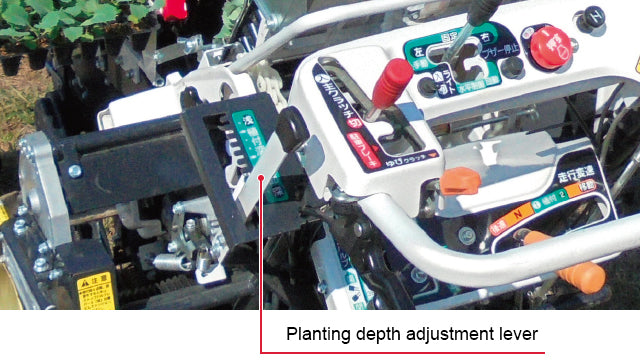

The transplant depth can be adjusted at the handle during operation.

The YANMAR Full Automatic Vegetable Transplanter transplants stably by automatic operations.

The YANMAR Full Automatic Vegetable Transplanter has two sensors on the front and back that allow to transplant from end to end of ridges.

The YANMAR Full Automatic Vegetable Transplanter automatically keeps transplanting level horizontal by automatically controlling the level.

The YANMAR Full Automatic Vegetable Transplanter is a high speed machine. Transplant speed is 0.52 m/s.

Seedling holding bar / 5 cell trays can be loaded / Holding empty cell trays / Consecutive seedling supplying structure

The Full Automatic Vegetable Transplanter has a wide range of planting distances selectable by a handle.

The YANMAR Full Automatic Vegetable Transplanter changes the direction of supplying cell trays according to the size of cell trays.

OPERABILITY

Most of the operation controllers are located around the handle.

RIDGE SHAPES

OPTIONS

We have a variety of option devices designed for PW10 Transplanter series. Please ask us for more information.

SPECIFICATIONS

| Model name | Full Automatic Vegetable Transplanter | ||||

|---|---|---|---|---|---|

| Model number | PW10 | ||||

| Type | M (1 row on 1 ridge, mulch) |

SW (1 row on 1 ridge, short planting distance) |

NRT (1 row on 1 ridge, narrow tread) |

||

| Dimension | Length (mm) | 2170 | |||

| Width (mm) | 980 | 1310 | 980 | ||

| Height (mm) | 1180 | 1180 | 1250 | ||

| Weight (kg) | 215 | 230 | 210 | ||

| Engine | Engine model | GB101LN | |||

| Type | Air-cooling 4 cycle gasoline engine | ||||

| Total engine displacement (L (cc) ) | 0.098 (98) | ||||

| Output / Rotational speed (kW (PS) /rpm) |

1.6 (2.2) /1800 | ||||

| Maximum output (kW (PS) ) |

2.2 (3.0) | ||||

| Fuel tank capacity (L) | 2.4 | ||||

| Starting method | Recoil starter | ||||

| Driving | Tread (mm) | 450 , 500 , 550 | 900 - 1400 | 460 - 510 | |

| The number of shift steps | Forward 3, backward 1 | Forward 2, backward 1 | Forward 3, backward1 | ||

| Speed | Planting (m/s) | F1:0.36 F2:0.42 |

0.19 | F1:0.42 F2:0.49 |

|

| Moving speed | Forward (m/s) | 1.05 | 1.00 | 1.22 | |

| Backward (m/s) | 0.35 | 0.35 | 0.41 | ||

| Body horizontality control device | Automatic, manual, fixed | ||||

| Angle value (degree) | Left and right 8 to 10 each | Left and right 4 to 5 each | Left and right 8 to 10 each | ||

| Planting | The number of planting rows | 1 | 1 (2 rows by going and returning) | 1 | |

| Ridge height (mm) | 0 - 300 | ||||

| Planting distance adjustment method | Stepless belt | ||||

| Planting distance (mm) | S:200 - 380 L:230 - 450 |

100 - 200 | F1:200 - 380 F2:230 - 450 |

||

| Planting depth adjustment (step) | Step (11 steps x 2) | ||||

| Planting method | Opening hole device | ||||

| Seedlings supplying method | Seedlings claws | ||||

| Mulch | Electric heater (temperature control) |

- | |||

| Operating efficiency (hour/10a) | 1.5 - 2.0 | 3.0 - 4.0 | 1.4 - 1.8 | ||

| The number of cell trays | 5 | 7 | |||

| Applicable vegetables | Cabbage, Chinese cabbage, broccoli, lettuce | Green onions, chrysanthemum (cabbage, Chinese cabbage, lettuce) |

Cabbage, Chinese cabbage, broccoli, lettuce | ||

| Cell trays | 25 - 200 holes, 30 - 128 holes | ||||

| Automatic planting depth control | YES | ||||

| Planting depth twin sensors | YES | ||||

| Soil covering roller width adjustment | NO | YES | |||

| Mud protection mat (protect soil covering roller from mud) |

YES | ||||

| Oil pressuring lock lever | At handle | ||||

| Stand attached to body | YES | ||||

| Whistle warning buzzer | YES | ||||

| Seedlings holding bar | YES | ||||

| Finger clutch (main clutch) | YES | ||||

| Empty tray holder | YES | ||||