SUMMARY

With rubber rolls and rocking sorting, you can finish the rice with confidence without sacrificing the quality of the rice.

FEATURES

There are two types of brown rice lift methods.

Models with GWAK in the product number are elevating type.

Model with GXAK in the part number is the thrower type.

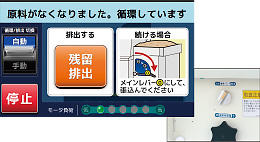

Operation panel

Equipped with a large screen color touch panel operation panel.

Driving procedures and driving status are displayed in an easy-to-understand animation. Anyone can easily perform hulling work by following the screen display.

When an error occurs, the buzzer sounds and a warning screen informs you.

The solution is displayed on the screen, so you can easily deal with it according to the screen display.

Skeleton mixed rice tank

Skeleton (transparent) material is used for the mixed rice tank. You can see the supply status of polished rice at a glance.

Equipped with automatic circulation discharge switching device

When the supply of paddy is interrupted during the rice hulling operation and the accumulation of the mixed rice tank decreases, the circulation discharge valve automatically switches from discharge to circulation.

At the end of hulling, it is possible to prevent the incorporation of chaff into refined products.

Roll clearance automatic control

The roll clearance is automatically adjusted to the optimum by Satake's original computer control, so you can finish delicious rice with confidence without sacrificing important rice quality.

VIDEO

SPECIFICATIONS

| Model Name | NRZ450GWAK |

|---|---|

| Required power (kW) |

3-phase 200V 2.79 |

|

Processing capacity (kg / h) (Brown rice discharge) |

1,080 - 1,440 (18-24 bales / hour) |

| Rubber roll (mm) | Integrated medium diameter 102 (4 inches) |

| Roll control | Automatic |

| Automatic circulation discharge switching | Available |

| Mixed rice lifting | Elevator |

| Brown rice lifting | Elevator |

|

Sorting method (Number of sorting plates) |

Swing sorting (7 plates) |

| Rice husk transport capacity (m) | Up to 16 (when light tube and steel tube are horizontal) |

|

Weight (kg) (Including motor) |

327 |

| Safety assessment conformity number | 39146 |